Instructions for use

Before wrapping

- In order to create well-formed bales, it is important that swathes are uniform in height, density and size and that they are the full width of the baler pick up.

- DM % should be between 35% and 50%. The wilting process should be completed within a maximum 36 hours after cutting.

- The film should be stored at a temperature of about 20% to 25% for at least 24 hours prior to use. This will increase the adhesive properties which are essential to obtain a good seal around the bale.

- It is crucial that the silage in the bale is not contaminated with soil.

- In addition to the DM %, special attention should be given to the density of the bale so that a) the silage quality is retained and b) the bale shape is retained for a longer period.

The Wrapping Process

Bales should be wrapped within 2 hours of baling.

During application MAXISTRETCH should be pre-stretched between 55 % and 70 %.

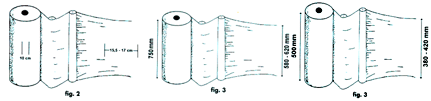

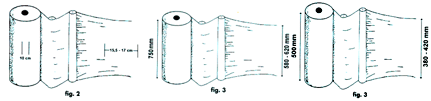

To check for correct percentage of film pre-stretch make two marks horizontally 10cm apart on the film reel. Slowly commence wrapping, and locate these marks on the bale surface and measure their distance apart. A 10 cm line marked on the roll should result in a length between 15.5 cm and 17 cm after pre-stretch. See Fig. 2.

The final width of film as measured on the flat end of a round bale should, with 750mm film be 580mm-610mm. See Fig.3. Should the film width vary significantly outside these limits, stop wrapping and ascertain cause. Refer to wrapper manufacturer with reference to PSU gearing.

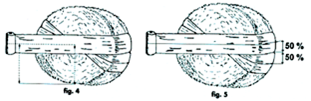

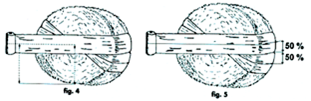

The film should be centred precisely in the middle of the bale. Adjust the height of the PSU where possible so that the centre points of reel and bale are horizontally aligned. Check that film overlap is no less than 50%. See Fig. 4 and Fig. 5.

Apply a minimum of 4 layers to all areas of the bale using the 2 + 2 method (see below) and a minimum 50 % overlap. Where DM levels exceed 50%, or square bales are being wrapped, a minimum of 6 layers of film should be applied using the 2+2+2 method (see below).

As any small area with less than 4 layers can result in severe moulding (because the seal in such an area would be insufficient), we strongly recommend working with a minimum of 6 layers on all bales.

2+2 and 2+2+2 Methods

To count the required rotations of the bale wrapping machine, follow the instructions below:

- Count the number of turntable rotations or sweep arm turns necessary to cover the bale completely once with a minimum 50% overlap. This number = X

- Add one rotation extra to this number i.e. X +1

- Multiply the result by 2 = ( X + 1 ) x 2, which will result in 4 layer coverage or

- Multiply the result by 3 = ( X + 1 ) x 3, which will result in 6 layer coverage

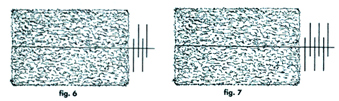

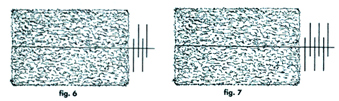

Special attention should be given to square bales, since they are more difficult to wrap. Square bales must be straight sided as any concave surfaces will produce air pockets when wrapped and possible spoilage. A minimum of 6 layers of films must be applied to all square bales.

When wrapping using a continuous tubeline system, a minimum 6 layers of film must be applied to the joins between the bales.

Please remember that in some cases even more film layers are required in order to protect the bale contents effectively. This could be the case for bales with a high content of course, stemmy crops; for bales in which the DM % is too low or for badly formed bales. In some extreme cases even 8 layers are recommended.

The standard rule is:

“The more layers around the bale, the better the protection is for the contents and the less risks there are!”

Load bale and place film reel on PSU so that outer film surface on reel will face inwards towards bale when applied. Follow the instructions accordingly. See Fig. 8)

It is strongly advised not to wrap during rain or hail showers since humidity decreases the adhesive properties of your film and may impair the seal between layers.

STORAGE CONDITIONS

Bale storage

- Ideally wrap at the storage point, and in the shade.

- If bales are not wrapped at the storage point, they must be transported and stored immediately after wrapping.

- Limit the number of times wrapped bales are handled / transported as much as possible in order to reduce the opportunities for damage to occur.

- Use a purpose-built handler when moving bales. Never use a spike.

- Any damage to the film should be repaired immediately, using UV resistant adhesive tape or by applying more wrap to the bale. N.B. Even minor damage to film can result in spoilage to fodder.

- Choose a well-drained level site, devoid of sharp objects which could damage the film. A sand or fine gravel surface is ideal.

- Choose a storage site away from trees and very exposed areas. Do not stack bales too close to trees and hedges.

- The bales should also be stored at least 10 metres from any watercourse.

- Store the bales for a maximum of one season. Use bales within 12 months of wrapping. Always feed any damaged bales first.

- To protect against birds, cover stack with close-woven polypropylene net, secured at ground level. For best protection, support net so that it is not in direct contact with the tops of bales.

- Fence off stack from livestock if necessary.

- Inspect stack regularly for damage caused by animals and vermin and repair any damage immediately.

- Several products of chemical origin can severely damage film. Keep film away from products like artificial fertilisers, insecticides, weed killers, mineral oil and solvents which can accelerate film degradation drastically.

- As certain chemical components such as sulphur and chlorine damage film dramatically, wrapped bales must be kept safe from such chemical products and components at all time.

- Do not wrap bales tied or netted with products which are chemically reactive to polythene such as some types of sisal twine.

- Do not wrap bales which have been treated with a sulphur-based additive.

- Do not stack bales more than 3 high.

- Round bales should be stacked preferably standing upright. Both round bales and square bales may be stacked on top of each other. Well-shaped bales with a high DM % may, if necessary, be stacked 3 high. It is recommended that well-shaped bales are stacked only 2 high. Under no circumstances, must the bales become deformed during the storage period. Bales of low DM or density should only be stored in single layers

- Silage stacks can be dangerous. Take appropriate safety precautions.

- Remove any visible spoilage within the bale on opening before feeding to livestock. Fodder which contains spoilage must not be fed to breeding stock or horses.

Storing the film

- Store the film in its original protective packaging and in a dry place, sheltered from sunlight.

- The MAXISTRETCH reel must be stored in upright position, on the pallet or off the ground and free from humidity.

In the event of complaint

If you are dissatisfied with any MAXISTRETCH reel either before or during wrapping, do not use. Replace in the original packaging and contact your supplier with full details of your complaint within 14 days.

The production reference number is marked on the label, which can be found in the reel core. The labels or the entire cores should be retained. Any complaint can only be considered if the correct details from the relevant production reference numbers can be provided.

The directions and recommendations contained in this document are based on our knowledge and practical experience. Since we cannot control the circumstances and conditions under which the film is stored or used, this document does not contain any guarantee and we accept no responsibility for the safe and proper use of the film.